-150.jpg)

Features

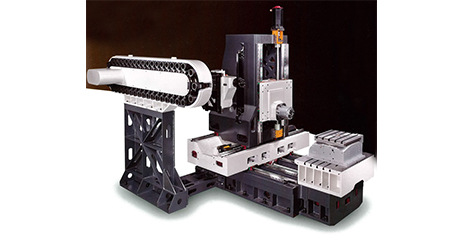

The machine's design structure is different from the light weight design philosphy in the past; it substantially consolidates the rigidity of body and parts structure, takes being more stable as the appeal, and adopts thick and solid sliding seat mechanism, slide way 1V1 flat structure, and lubrication system designed by the hydrostatic principle, providing the best precision and stability of moving when doing grinding.

- Newly developed EXTOMAX breaks through the original limited design of medium- and small-sized machine tools.

- Re-enforced structure, low gravity and high rigidity machine base, made of Meehanite cast iron through annealing and aging treatment, incorporated into a no-deformation and precise machine body.

- Longitudinal and traverse sliding tables, with enlarged overall stride and rail way width, precision scrapping made on both horizontal and vertical sides, coupling with hydrostatic structure, light and steady movement of sliding table, repeated precision reaching up to µ level.

- Grinding wheel spindle designed with hydrostatic bearing, free of metal friction and thermal deformation, allowing smooth within the oil film operation of spindle.

- Workhead and tailstock specially designed for heavy duty work, high rigidity structure, increasing overall loading capacity. Workhead is driven by servo motor, providing step-less variable speed change. Supported by precision bevel bearing, attains vibration free transmission ability. Tailstock equipped with hydraulic and stopper for easy operation, horizontal air bearing designed for easy displacement, reducing friction and increasing longevity.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)